Unlock the Power of Automation: Discover the Secrets of IGBT Modules!

In the fast-paced world of automation, where efficiency and reliability are paramount, the Insulated Gate Bipolar Transistor (IGBT) has emerged as a fundamental component. This semiconductor device plays a vital role in converting and controlling electrical power, making it indispensable for various automation projects. As industries strive for improved performance and energy savings, the demand for efficient power solutions has skyrocketed. IGBT modules are at the forefront of this revolution, offering unique capabilities that enhance the operation of everything from motor drives to renewable energy systems. In this article, we will delve into the intricacies of IGBT technology, explore its applications, provide insights on selecting the right module, and discuss the future trends shaping this essential component of modern automation.

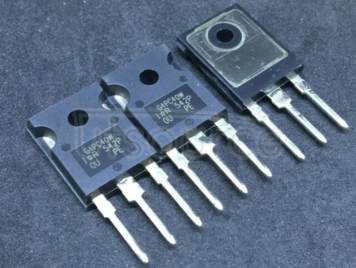

Understanding IGBT Technology

IGBT technology combines the advantages of two important semiconductor devices: the MOSFET and the bipolar transistor. The result is a device that has high input impedance and can handle large amounts of current. The working principle of an IGBT revolves around the ability to control the flow of electrical energy with minimal losses, making it particularly effective in switching applications. One of the standout features of IGBTs is their ability to operate at high voltages and currents while maintaining excellent thermal performance. This unique combination makes IGBTs ideal for automation applications where energy efficiency is crucial. For instance, a friend of mine who works in an industrial automation firm noted how switching to IGBT modules helped reduce their energy consumption significantly, showcasing the practical benefits of this technology.

Applications of IGBT Modules in Automation

IGBT modules find their applications across various sectors of automation, including motor drives, renewable energy systems, and industrial automation. In motor drives, they enable precise control over speed and torque, which is essential for optimizing performance and efficiency in applications like electric vehicles and conveyor systems. In renewable energy systems, IGBTs are used in inverters to convert DC from solar panels into AC for grid compatibility, significantly enhancing energy conversion rates. Additionally, industrial automation benefits from IGBT modules in processes such as welding and power supply systems. A colleague of mine who specializes in renewable energy reported that incorporating IGBT modules in their inverters improved the overall system efficiency by 20%, highlighting the impact of this technology in real-world applications.

Choosing the Right IGBT Module

When selecting IGBT modules for your automation projects, there are several key factors to consider. Firstly, voltage and current ratings are critical, as they determine the module's capacity to handle specific loads. Thermal performance is another essential aspect; a module that can dissipate heat effectively will ensure reliability and longevity in demanding environments. Package types also play a role in compatibility with existing systems. It is essential to evaluate specifications thoroughly and understand datasheets, as they provide vital information that can guide your selection process. I recall a situation where a friend miscalculated the voltage rating for their project, which led to overheating issues. This experience emphasizes the importance of careful consideration when choosing the right IGBT module.

Future Trends in IGBT Technology

The landscape of IGBT technology is constantly evolving, with emerging trends that promise to enhance its capabilities further. Innovations aimed at improving efficiency and reducing size are at the forefront of development. For instance, advancements in materials and design are leading to more compact IGBT modules that deliver higher performance without compromising on heat dissipation. Additionally, the integration of IGBTs with other technologies, such as digital control systems, is paving the way for smarter automation solutions. These trends not only improve the functionality of automation projects but also align with the growing emphasis on sustainability and energy efficiency. As I discussed with a fellow engineer, these advancements could revolutionize how we approach future automation challenges, making it an exciting time for those involved in this field.

Key Takeaways on IGBT Modules

In conclusion, IGBT modules are a cornerstone of modern automation, providing efficient power solutions that enhance performance across various applications. Understanding the intricacies of IGBT technology, from its working principles to its practical applications, equips users with the knowledge needed to make informed decisions in their projects. As the industry continues to evolve, keeping abreast of trends and advancements in IGBT technology will empower you to harness its full potential. Whether you're involved in industrial automation, renewable energy, or any other sector, exploring IGBT options could be the key to achieving your automation goals.