Transform Your Distribution Center with the Ultimate Linear High Bay LED Retrofits!

As distribution centers evolve to meet the demands of modern logistics, upgrading lighting systems has become paramount. Enter linear high bay LED retrofits—an innovative solution designed to enhance visibility, reduce energy consumption, and improve overall working conditions in large spaces. These retrofits are not just a trend; they represent a significant step towards sustainability and operational efficiency. By transitioning to LED technology, facilities can enjoy a host of benefits, including substantial cost savings on energy bills and maintenance, along with an environment that promotes productivity and safety. Imagine a brighter, more efficient workspace where employees feel energized and focused; that’s the promise of linear high bay LED retrofits.

Understanding Linear High Bay LED Retrofits

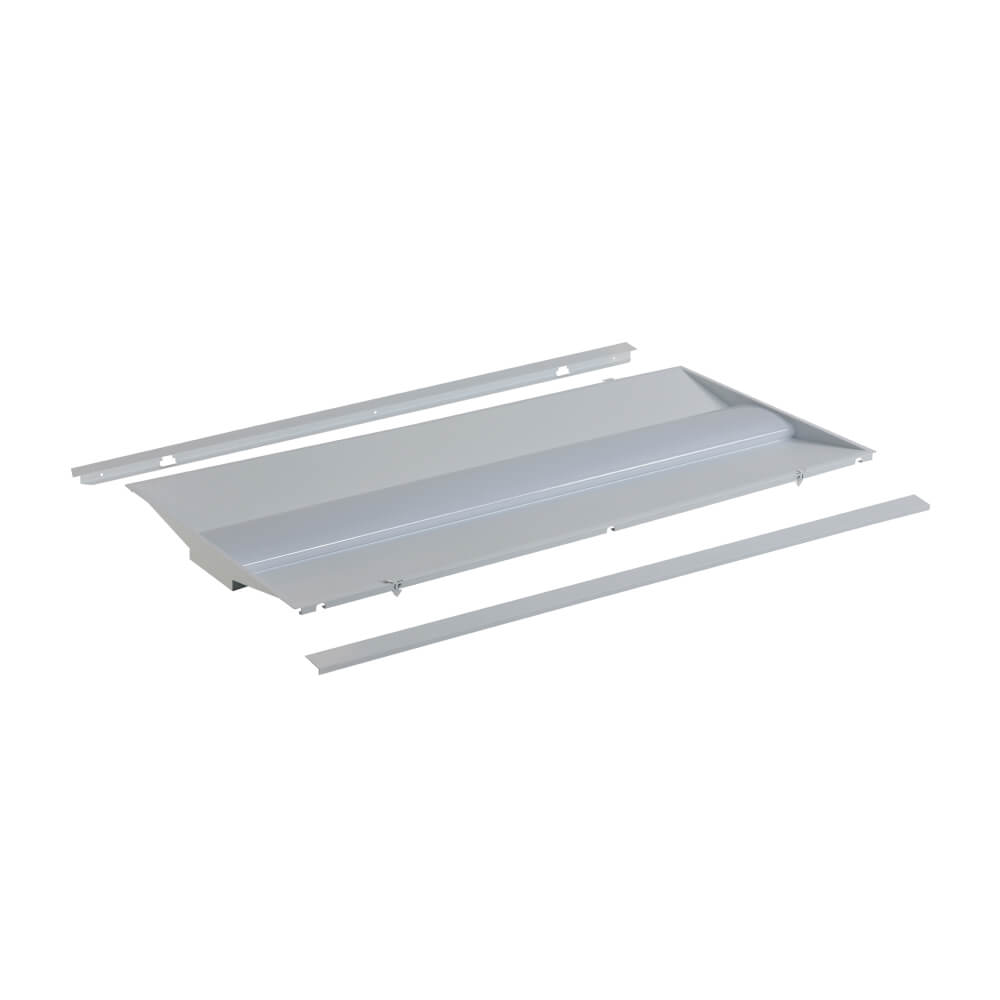

Linear high bay LED retrofits are specialized lighting solutions designed to replace traditional high bay fixtures in large industrial spaces, such as distribution centers. These retrofits work by utilizing advanced LED technology, which offers superior illumination while consuming significantly less energy compared to conventional lighting systems. Typically, high bay fixtures are mounted at considerable heights, making it essential for the lighting to provide uniform brightness across expansive areas. The design of linear high bay LEDs focuses on achieving this goal by distributing light evenly and reducing shadows, ensuring a well-lit environment that enhances safety and productivity. Furthermore, these retrofits can be seamlessly integrated into existing lighting setups, making them an appealing option for facilities looking to upgrade without a complete overhaul.

Benefits of Upgrading to LED Retrofits

Upgrading to linear high bay LED retrofits comes with a multitude of benefits that can transform the operational landscape of a distribution center. One of the most significant advantages is energy efficiency; LED lights consume up to 75% less energy than traditional lighting solutions. This reduction not only leads to lower utility bills but also contributes to a smaller carbon footprint, aligning with sustainability goals. Additionally, LED lights boast an impressive lifespan of up to 50,000 hours or more, which means reduced maintenance costs and fewer replacements. The quality of illumination also improves dramatically, with LEDs providing brighter and more consistent light that enhances visibility and reduces eye strain among workers. All these factors combine to create a more efficient, cost-effective, and healthier working environment.

Factors to Consider When Choosing LED Retrofits

When selecting linear high bay LED retrofits for a distribution center, several critical factors should be taken into account. First and foremost is lumen output; it’s essential to choose fixtures that provide sufficient brightness for the specific tasks performed in the space. Also, consider the color temperature of the lights; a cooler color temperature (around 5000K) can enhance focus and alertness, which is ideal for bustling environments. Compatibility with existing fixtures is another important consideration, as some retrofits may require specific adapters or modifications for installation. Lastly, installation ease can significantly affect the overall cost and timeline of the project; opting for retrofits that are designed for straightforward installation can minimize downtime and labor costs.

Case Studies: Successful Implementations

Many distribution centers have reaped the rewards of implementing linear high bay LED retrofits, showcasing the transformative impact of this technology. For instance, a large distribution center in the Midwest recently upgraded its lighting system, resulting in a staggering 60% reduction in energy costs. Employees reported feeling more alert and productive in the well-lit environment, and the center experienced fewer accidents due to improved visibility. Another success story comes from a facility that integrated LED retrofits during a recent renovation. After the upgrade, they noted a significant decrease in maintenance calls related to lighting, as well as an overall improvement in employee morale. These case studies illustrate that the transition to LED lighting is not just a financial investment but also a commitment to creating a better workplace.

Summarizing the Benefits of LED Retrofits

In conclusion, linear high bay LED retrofits represent a powerful solution for distribution centers looking to enhance their lighting systems. The benefits—including energy efficiency, reduced maintenance, and improved illumination—are compelling reasons to consider this upgrade. With numerous successful implementations showcasing the positive outcomes, it’s clear that the transition to LED technology can lead to a brighter, more efficient, and safer working environment. If you’re evaluating your facility's lighting needs, now is the perfect time to explore the advantages of linear high bay LED retrofits and take the first step towards transforming your distribution center.