Unlock the Secrets of Vapor Tight LED Lighting: Discover the Best Manufacturers in China!

Vapor tight LED lighting is an innovative solution that has transformed how industries approach their lighting needs, particularly in challenging environments. These fixtures are designed to withstand harsh conditions, including moisture, dust, and chemicals, making them ideal for applications in warehouses, manufacturing plants, and even outdoor settings. As industries increasingly prioritize energy efficiency and durability, the demand for vapor tight LED lighting is on the rise. In this article, we will explore the technology behind vapor tight LED lighting and delve into the leading manufacturers in China, a country renowned for its advanced manufacturing capabilities and competitive pricing.

Understanding Vapor Tight LED Lighting Technology

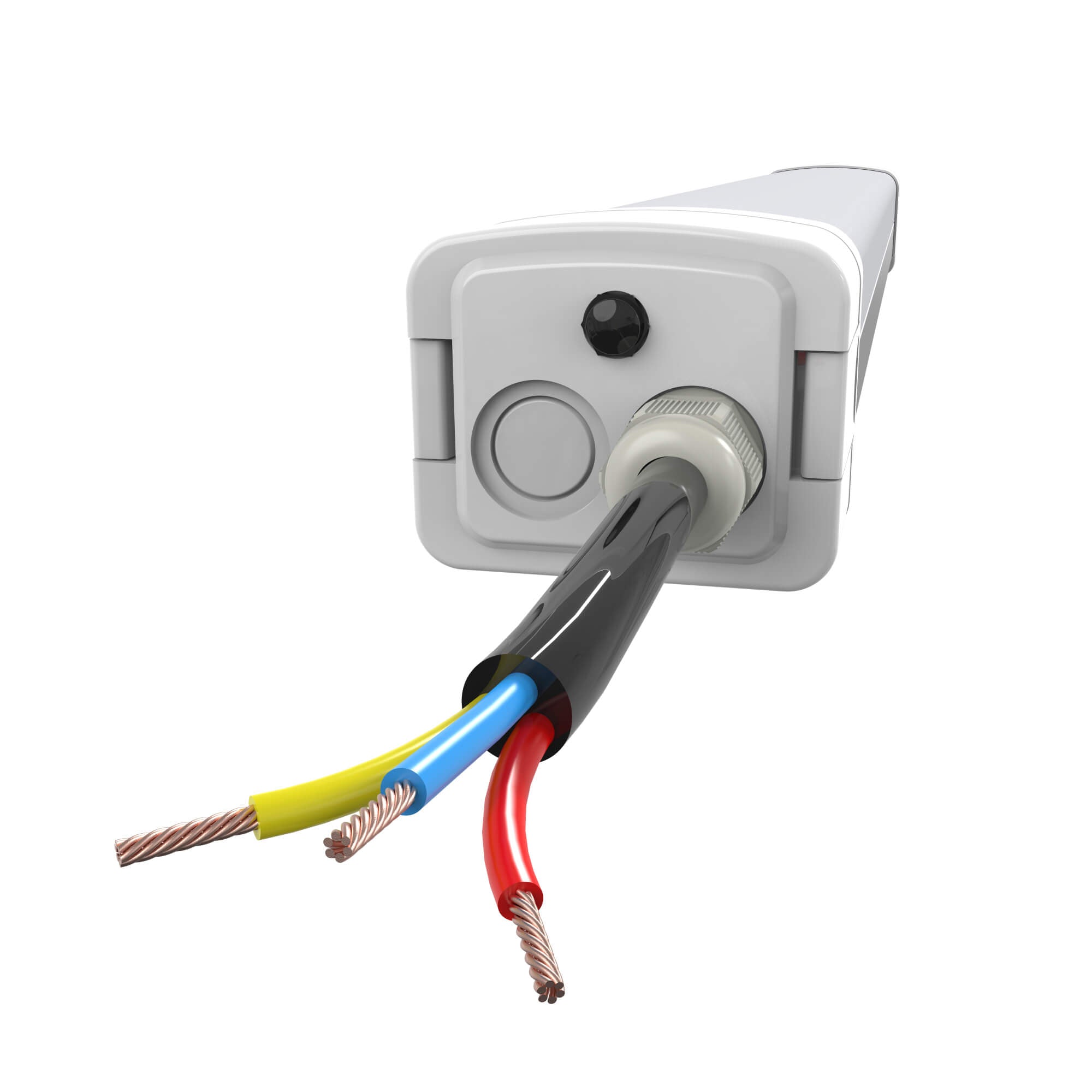

Vapor tight LED lighting refers to luminaires that are specifically designed to prevent moisture and dust from entering the fixture, ensuring reliable performance in demanding environments. These fixtures typically feature a sealed enclosure, often made from robust materials such as polycarbonate or tempered glass, which enhances their durability. The working principle of vapor tight LED lights involves the use of light-emitting diodes (LEDs) that convert electrical energy into light with remarkable efficiency. One of the standout features of vapor tight LED technology is its energy efficiency; these fixtures consume significantly less power compared to traditional lighting solutions, leading to substantial cost savings over time. Additionally, the longevity of LED technology—often exceeding 50,000 hours—means fewer replacements and reduced maintenance costs. The ability to resist environmental factors such as humidity, dust, and corrosive substances makes vapor tight LED lighting a reliable choice for industrial and commercial settings, where operational uptime is critical.

The Importance of Choosing a Reliable Manufacturer

When selecting a manufacturer for vapor tight LED lighting, several critical factors must be considered to ensure the best product quality and performance. Quality control is paramount; a reputable manufacturer should have stringent testing procedures and certifications that validate the durability and efficacy of their products. Certifications such as ISO and CE indicate adherence to international quality standards. Production capacity is another essential consideration; manufacturers that can scale production are better equipped to handle bulk orders without compromising quality. Additionally, customer support plays a vital role in the overall experience; a responsive manufacturer can provide guidance, address concerns, and assist with installations, ensuring that clients can maximize the benefits of their lighting solutions. The choice of a reliable manufacturer directly impacts the longevity and performance of vapor tight LED lighting, making it crucial for businesses to conduct thorough research and due diligence before making a decision.

Top Features to Look for in Chinese Vapor Tight LED Manufacturers

As you explore potential manufacturers for vapor tight LED lighting in China, several essential features should guide your research. First, technology advancements are vital; manufacturers that invest in the latest lighting technologies are more likely to offer innovative and energy-efficient products. Customization options are also important; many industries have unique lighting requirements, and a manufacturer that can tailor solutions to fit specific needs will have a competitive edge. Warranty policies provide additional peace of mind; look for manufacturers that offer robust warranties, as this indicates confidence in their product quality. Compliance with international standards is another non-negotiable aspect; manufacturers that adhere to global standards ensure their products are safe and reliable for international use. By focusing on these key features, businesses can identify manufacturers that align with their needs and values.

Notable Trends in the Vapor Tight LED Market in China

The vapor tight LED market in China is witnessing several notable trends that are shaping the future of industrial lighting solutions. One significant trend is the integration of smart technology; many manufacturers are now offering smart vapor tight LED fixtures equipped with sensors and connectivity features that enhance functionality and energy savings. These smart solutions allow users to control lighting remotely, adjust brightness, and even monitor energy consumption in real-time. Sustainability initiatives are also gaining momentum, with manufacturers focusing on environmentally friendly materials and production processes to reduce their carbon footprint. Additionally, evolving design aesthetics are influencing the market; contemporary vapor tight fixtures are being designed not only for functionality but also to fit modern industrial aesthetics, making them suitable for a broader range of applications. These trends are indicative of a market that is not only responding to the current demands but also anticipating future needs in lighting technology.

Key Takeaways on Vapor Tight LED Lighting

In summary, vapor tight LED lighting technology offers a reliable and efficient solution for industries that operate in challenging environments. Understanding the technology, the importance of selecting a reputable manufacturer, and the features to look for can significantly impact the performance and longevity of lighting solutions. With the ongoing trends in smart technology and sustainability, the future of vapor tight LED lighting looks promising. As you embark on your search for a manufacturer, remember to conduct thorough research and consider the outlined factors to ensure you make an informed decision that meets your lighting needs.