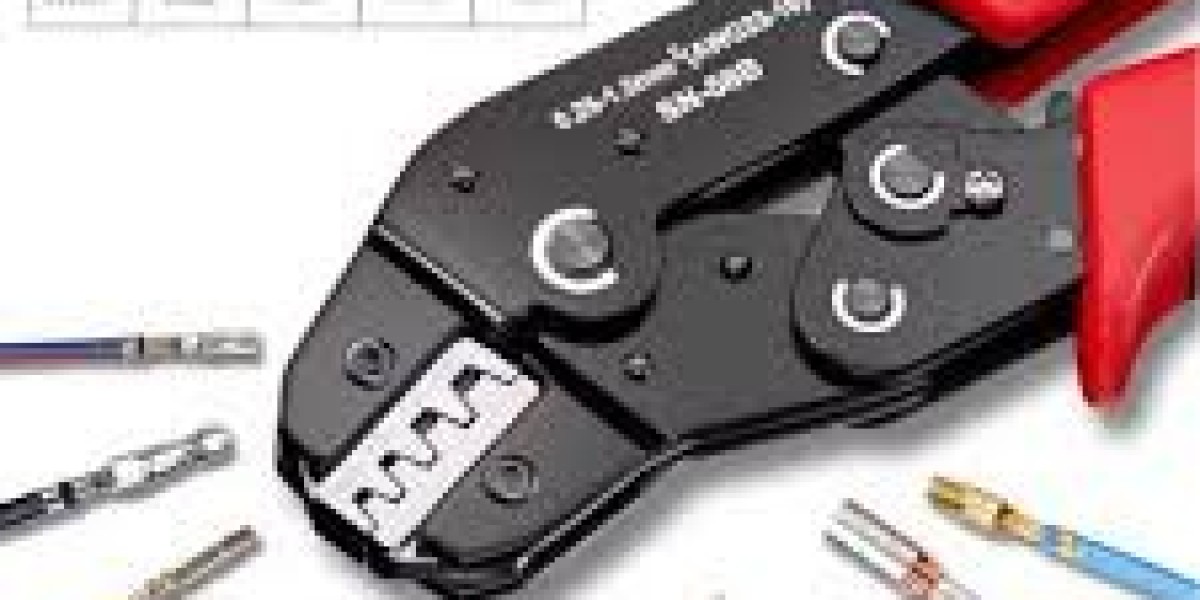

Introduction: Why Precision Matters in Every Connection

In the world of electrical work, automotive repair, and network installation, the smallest details determine long-term performance. One loose wire can cause system failure. One poor connection can lead to costly downtime. This is where a crimping tool becomes more than just a handheld device — it becomes a precision instrument that ensures strength, safety, and reliability.

Whether you’re a professional technician or a DIY enthusiast, understanding how a crimping tool works and why it matters can dramatically improve the quality of your projects.

What Is a Crimping Tool?

A crimping tool is a specialized hand tool designed to join a connector to the end of a wire by deforming one or both of them to hold each other securely. Instead of soldering, crimping creates a mechanically solid and electrically stable connection.

The process involves inserting a stripped wire into a connector and compressing it using the crimping tool. The result is a tight bond that resists vibration, corrosion, and electrical resistance issues.

Unlike temporary fixes, crimped connections are engineered for durability — which is why industries rely on them daily.

Types of Crimping Tools and Their Applications

Not all crimping tools are built the same. Different projects demand different levels of pressure and precision.

1. Manual Crimping Tool

Ideal for small electrical jobs, home wiring repairs, and light-duty connectors. These are affordable, portable, and easy to use.

2. Ratcheting Crimping Tool

Designed for consistent pressure application. The ratchet mechanism ensures the tool fully compresses before releasing, making it perfect for professional electrical work.

3. Hydraulic Crimping Tool

Used for heavy-duty industrial cables and thick wiring systems. It delivers maximum compression force with minimal effort.

4. Network Crimping Tool

Specifically created for Ethernet and data cables like RJ45 connectors. Essential for IT technicians and network installers.

Choosing the right crimping tool depends entirely on the type of connector, wire gauge, and project scale.

Why a High-Quality Crimping Tool Is Worth the Investment

Many people underestimate the importance of tool quality. However, using a low-grade crimping tool can result in:

Weak electrical contact

Increased resistance

Overheating issues

Connection failure under vibration

A premium crimping tool provides uniform compression, ergonomic handling, and long-term durability. This ensures every crimp is secure and consistent — reducing the risk of electrical faults.

Professionals understand that reliability begins at the connection point.

Key Features to Look for in a Crimping Tool

When selecting a crimping tool, consider the following features:

Adjustable Crimping Dies

Interchangeable dies allow compatibility with various connector sizes.

Ergonomic Grip

Comfort matters during extended use. Non-slip handles improve control and reduce fatigue.

Precision Alignment

Proper alignment ensures clean, accurate crimps every time.

Built-In Wire Cutter and Stripper

Some multi-function crimping tools combine cutting and stripping capabilities, improving efficiency.

Smart tool selection enhances productivity while maintaining professional standards.

Common Mistakes to Avoid When Using a Crimping Tool

Even the best tool cannot compensate tool crimping for improper technique. Here are mistakes to avoid:

Using the wrong connector size

Not stripping the wire correctly

Applying uneven pressure

Over-crimping and damaging the connector

Proper training and attention to detail are essential for achieving safe and lasting results.

Industries That Depend on Crimping Tools

A crimping tool is not limited to electricians. It plays a critical role across various industries:

Automotive manufacturing

Telecommunications

Aerospace engineering

Renewable energy systems

Home electrical installations

Anywhere reliable wiring is required, crimping tools are indispensable.

Crimping Tool vs. Soldering: Which Is Better?

While soldering has its place, crimping offers distinct advantages:

Faster installation

No heat damage

Strong mechanical hold

Better resistance to vibration

In many professional settings, crimped connections are preferred because they combine electrical conductivity with structural integrity.

Final Thoughts: Small Tool, Big Impact

A crimping tool may seem simple at first glance, but its impact on electrical safety and performance is significant. From household wiring to industrial systems, secure connections are the backbone of every powered device.

Investing in the right crimping tool — and using it correctly — ensures your projects remain efficient, durable, and safe.

Read More Latest Articles: Clicking Here